The different 3D printing technologies make use of additive manufacturing. Technologies like fused deposition modeling, selective bar sintering, stereolithography, material jetting, and others.

Some of these processes are capable of carrying out wax 3D printing. For it to work, a few things have to be put in place. You have to make the right arrangements and click the right keys.

Additive manufacturing offers an opportunity for makers to print almost anything of their choice. They now have the leverage of using a variety of materials to print.

They can choose to use metal, plastic resin, or even wax. Makers have developed different ways to print wax.

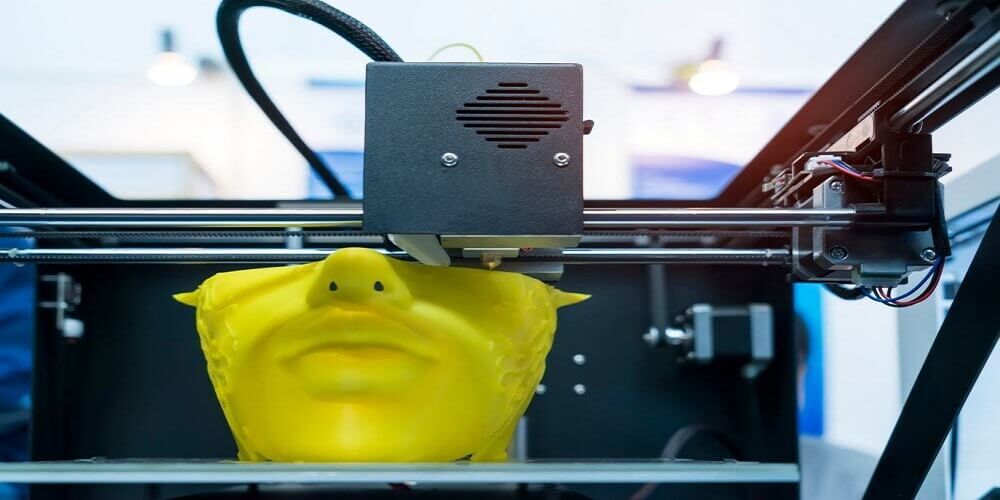

3D Printing with Wax

Contrary to popular opinion, the material used in wax 3D printing is not exactly pure natural wax. Yes, it is hard to believe. But it is true. The material used for wax 3D printing is wax-like

The fact that it has some similar physical properties to wax, makes it easy to put under the wax category.

How Do You Use Wax for 3D Printing?

Using wax to print 3D can be achieved with numerous techniques.

The wax used in 3D printing can create a specific 3D mold from a 3D file. You should thank the 3D lost wax casting technique for that.

The 3D lost wax casting also known as investment casting is a well-known production process. This process allows makers to create high-quality customizable jewelry.

With this production process, the maker is also able to create complex 3D designs from various printing materials. Instead of wax, the maker can create a complex design from metal.

The production process known as investment casting or more commonly known as 3D lost wax casting is simply amazing.

The main idea is to create a new concept with3D and then 3D printing its patterns with wax. The wax printing of any pattern is performed with a wax 3D printer.

The model is then covered with the refractory material to get a mold. The melting wax filament is then layered into the mold.

This then creates space inside the mold which is later filled with molten metal from the 3D printer. After the whole process has been completed, it is allowed to cool.

Many different finishes can be done to any piece of waxed d printed jewelry. But the main goal is for them to look perfect, shiny, and presentable.

Another method commonly used to wax 3D print is material jetting.

Material jetting in wax 3D printing is also very common. A lot of jewelry makers have adopted it to make quality jewelry as part of their business.

Material jetting is a 3D printing technology that builds multiples layers of printing material droplets under ultraviolet (UV) light.

Just like other 3D printer technologies, when the top layer is complete, the build-platform lowers automatically for the next layer to resume printing.

Conclusion

The basic use of 3D printed wax is for wax printing 3D printed jewelry or dental molds. There are a lot of 3D materials and technologies as well as 3D finishes that will serve whatever project you wish to take on.