If you talk blow molding you might need referencing to forms of plastic molding because blow molding is indifferent. The assembling procedure by which empty plastic parts are framed: It is likewise utilized for shaping glass bottles.

History of Blow Molding

The procedure rule originates from the possibility of glassblowing. In 1938 after forming a blow-molding machine, Enoch Ferngren and William Kopitke vended it to Hartford Empire Company in 1938. This was the start of the business blow shaping procedure. Amid the 1940s the assortment and number of items was still exceptionally restricted and accordingly brush shaping did not take off until some other time. Once the assortment and generation rates went up the quantity of items made took after soon a short time later.

In the United States soda industry, the quantity of plastic compartments went from zero of every 1977 to ten billion pieces in 1999. Today, even a more prominent number of items are blown and it is relied upon to continue expanding.

For formless metals, otherwise called very metallic glasses, blow shaping/molding has been as of late exhibited under weights and temperatures tantamount to plastic blow molding.

What is Blow Molding?

The blow shaping procedure starts with liquefying down the plastic and framing it into a parison is a tube-like bit of plastic with an opening in one end through which compacted air can pass. The parison is then clasped into a shape and air is blown into it. It implores three primary kinds:

- Expulsion blow forming

- Infusion blow trim

- Infusion extend blow shaping.

The pneumatic force at that point pushes the plastic out to coordinate the shape. Once the plastic has cooled and solidified the form opens up and the part is launched out. The cost of blow formed parts is higher than that of infusion – shaped parts however lower than rotational formed parts.

-

Expulsion Blow Forming (EBM)

In expulsion, blow-forming plastic is dissolved and expelled into an empty tube: a parison. This parison is then caught by shutting it into a cooled metal form. Air is then blown into the parison, swelling it into the state of the empty jug, compartment, or part.

EBM procedures can be either persistent or irregular. You can arrange the kinds of EBM gear after:

- Nonstop expulsion gear

- Revolving wheel blow forming frameworks

- Carry hardware

- Irregular expulsion apparatus

- Responding screw hardware

- Aggregator head apparatus

Cases of parts made by the EBM procedure incorporate most polyethylene empty items, drain bottles, cleanser bottles, car ducting, watering jars and empty mechanical parts, for example, drums.

-

Turn trimming.

Holder’s jostles frequently have an abundance of material because of the trim procedure. This is trimmed off by turning a blade around the holder, which removes the material.

This overabundance plastic is then reused to make new moldings. Turn Trimmers are utilized on various materials, for example, PVC, HDPE and PE+LDPE. Distinctive sorts of the materials have their own particular physical attributes influencing trimming.

-

Infusion blow forming.

The procedure of infusion blow forming (IBM) is utilized for the creation of empty glass and plastic protests in expansive amounts. In the IBM procedure, the polymer is infusion formed onto a center stick; at that point, the center stick is turned to a blow shaping station to be swelled and cooled.

This is the minimum utilized of the three blow shaping procedures, and is commonly used to make little medicinal and single serve bottles. The procedure is separated into three stages: infusion, blowing and discharge.

The infusion blow-forming machine depends on an extruder barrel and screw gathering which dissolves the polymer. The liquid polymer is nourished into a hot sprinter complex where it is infused through spouts into a warmed cavity and center stick.

-

Infusion extend blow shaping.

This has two fundamental diverse techniques, in particular Single-stage and two-arrange process. Single-organize process is again separated into 3-station and 4-station machines. In the two-organize infusion extend blow forming process; the plastic is first shaped into a “preform” utilizing the infusion shaping procedure.

These preforms are created with the necks of the jugs, including strings toward one side. These preforms are bundled and sustained later; subsequent to cooling into a warm extend blow-shaping machine. In the ISB procedure, the preforms are warmed; ordinarily utilizing infrared radiators over their glass progress temperature, at that point blown utilizing high-weight air into bottles utilizing metal blow molds.

The preform is constantly extended with a center pole as a major aspect of the procedure. Points of interest: Very high volumes are delivered.

Little confinement on bottle outline. Preforms can be sold as a finished thing for an outsider to blow. Is appropriate for round and hollow, rectangular or oval containers. Drawbacks: High capital cost. Floor space required is high, albeit smaller frameworks have turned out to be accessible.

In the single-organize process both preform produce and jug blowing are performed in a similar machine. The more established 4-station strategy for infusion, warm, extend blow and launch is more exorbitant than the 3-station machine which wipes out the warm stage and uses inert warmth in the preform, along these lines sparing expenses of vitality to warm and 25% decrease in tooling.

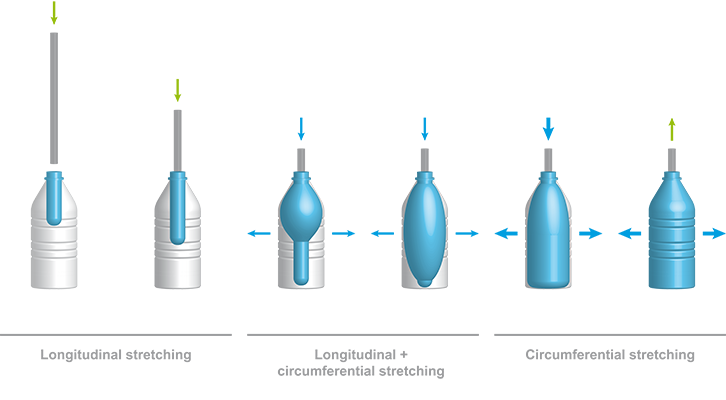

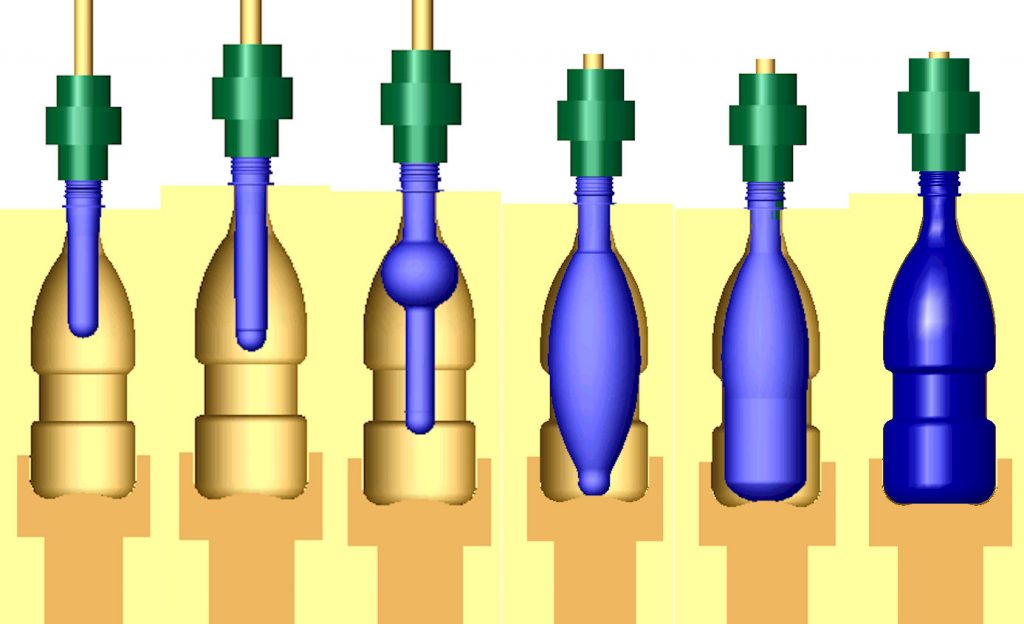

The procedure clarified; Imagine the particles are little round balls, when together they have huge air holes and little surface contact, by first extending the atoms vertically then blowing to extend evenly the biaxial extending makes the particles a cross shape.

These “crosses” fit together leaving little space as more surface territory is reached in this manner making the material less permeable and expanding obstruction quality against penetration. This procedure likewise expands the quality to be perfect for loading with carbonated beverages.

Advantages of Blow Molding

- Highly appropriate for low volumes and short runs. As the preform is not discharged amid the whole procedure, the preform divider thickness can be molded to permit even divider thickness when blowing rectangular and non-round shapes.

Disadvantages of Blow Molding

- Restrictions on bottle outline. Just like a champagne base can be formed for carbonated jugs.

Conclusion

This technology is being embraced with many manufacturing company. If you are a molding company I strongly encorage you to use this technique.