An orifice gadget fixed on the hydraulic tube or hose line comes with specified cost-effective adapters or orifice fittings. These adapters eliminate costly flow control valves in the hydraulic system and pipelines. Additionally, each hydraulic tube is fitted with the correct hydraulic orifice fitting for effective operation. Are these parts safe?

How orifice fittings parts are essential for safe operation

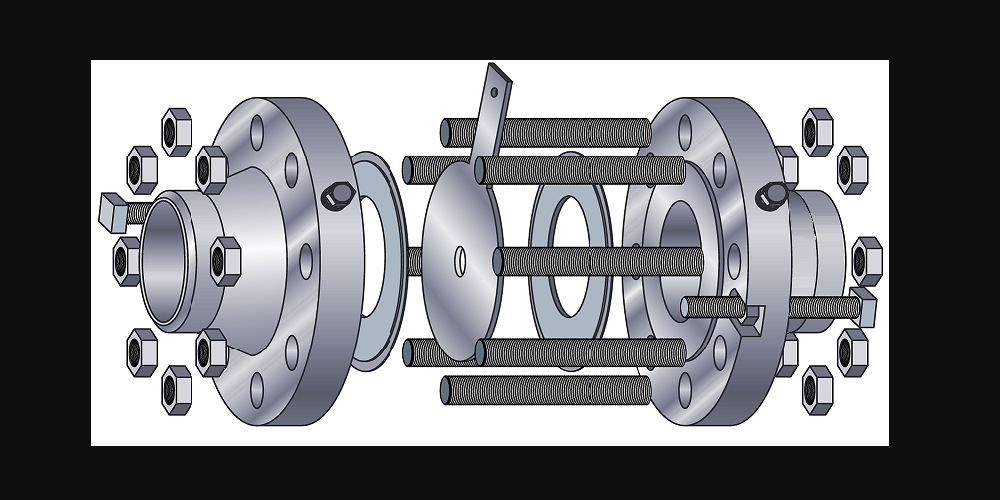

Proper use of orifice fittings is necessary to ensure the safety of the equipment and to guarantee its long life. You must inspect the orifice plate well and ensure it fits to ensure equipment safety. At the same time, select proper orifice sizes at the factory. That way, there will be no need to adjust the existing flow and velocity of the hydraulic system. Here’s more to that:

Orifice fittings come in perfect sizes

The tools come in two different sizes, and they are designed to allow for both temporary and perpetual fixings. They are easy to install into the hydraulic structure by linking the tube pivot and converter. Ensuring the body fits perfectly well is vital to avoid costly flow control valves. In addition, these fittings are used in fixed rotation speed for hydraulic pipeline motors.

The fittings employ modernization

The di-chamber orifice fixtures are well modernized. They allow for a straightforward and fast technique for altering or scrutinizing orifice plates under compression. With the ball-shaped structure, the system unlocks and shuts without using complex gear machinery. In addition, the fittings operate without the need for manual lubrication as they lubricate themselves in the process. They are also fitted with an orifice seal that ensures total sealing around the orifice.

Well compartmentalized

The mono compartment orifice fitting is intended to help install and examine the orifice plate. The sole chamber has minimal parts, and it is cheaper to use and provides an easy way of removing an orifice plate without the shutdown time.

Presence of screen fittings

Component failure can find its way into the system during installation, even when filtration occurs. For that reason, screen fittings are to ensure high quality by prohibiting any particles from finding their way into the system. They work with a high-quality filtration system, and their primary purpose is to protect the gauges and the instruments. They also offer protection to critical hydraulic components and precision orifice from clogging; they are needed in some of the expensive components to test circuits and ensure there is no particle contamination

Assured assembling

You can use an orifice plate retainer to assemble twofold and solo chamber orifice fittings. The tool has a holder and a chamber cap to control the orifice positioning. When the orifice is situated in the wrong place, the lid won’t close. At the same time, the lid aligns the plate automatically when it is wrongly centered. The orifice plate holder and the merging ring are covered with nickel to resist corrosion. At the same time, the merger and the O-ring hold the device plate in a good location for better operation.

Your installations are safe with the best orifice fittings

These fittings and many others help the pipeline system work well and ensure safety in the entire operation. The most important thing is to ensure you order your hydraulic orifice fitting from quality suppliers like us. That will ensure you have precise and quality fittings that will guarantee safety.