Essential Elements of the Injection Molding Process

An injection mold manufacturer is a firm that uses the process of injection molding for the manufacture of parts and tools. Injection molding can be defined as the process through which molten plastic is injected into sections known as mold cavities and cooled down to form solid plastic parts. The injection process is done using a nozzle.

The mold cavities are designed according to the geometrics and overall design of the product intended for manufacture. The mold design is, therefore, the most crucial part of injection molding, and nothing can be achieved without this part. Injection molding in an accessible mode of manufacturing because it helps in the production of several elements in a cost-efficient and time-efficient manner. In this post, we discuss the significant components of injection molding.

The Mold

The mold, also referred to as die, is a tool from which plastic parts are produced in the process of injection molding. The design of the parts significantly influences the design of the mold. But, constructing a single mold is very costly. Therefore, to reduce the costs of production, a unique mold is used to make several thousand parts.

Molds are made from a variety of elements. The elements have to be sturdy to handle the heat of the molten plastic. Some of the common materials from which the mold is made are aluminum and hardened steel. The materials from which the molds are constructed also affect the cost of manufacturing.

There are two primary components of the mold design;

The mold design, as it affects the final injection results. This is regardless of the size, gate position, size of the main inserts, a system through which the mold is run, cooled, and position of injection.

- The injection mold- this is the part that receives the plastic resin through a gate. Once the resin is inside this plate, it is sealed tightly to allow the plastic, which at this point, is in molten form to flow into the cavities. The cavities resemble the shape and design of the part.- The ejector mold- this plate is known as the mold maker

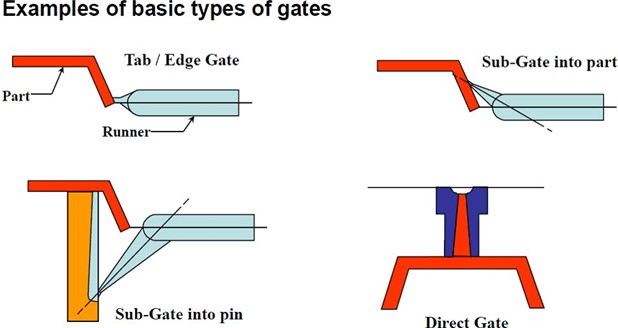

Types of molding gates****

- Direct gate- it is also known as the sprue gate and used in the production of broad. It is also ideal for parts whose designs don’t allow gate marks on the outside; hence the gate could be designed in the interior part. - Side gate- this is a merely structured mold gate that is easier to remove and enables effortless processing. - Tab gate- this is an advancement from the side gate and most suitable for preventing plastic jetting. It is ideal for flat plastic parts that are more specific on the surface finish.

Bottom Line

The injection unit is made up of three main components called the screw motor, reciprocating screw, and the ring plunger. Another essential element is the clamping unit, which is made up of the mold, the clamping motor drive, and the tie bars.