An Automatic Recycling Valve refers to a pump protection device. It protects the centrifugal pump, particularly when the body of the pump encounters cavitation damage. When the pump flow is low compared to the normal flow, a bypass may open to help in making sure that the minimum needed flow pump is achieved. Here are additional facts about an automatic recycling valve.

- Providing Solutions For Pump Protection

Modern industrial equipment processes have demands for centrifugal pumps. They work under some conditions. An ARC valve is a multifunctional channel whose main purpose is to make sure that a pre-determined flow is achieved via a centrifugal pump. This should occur at all times.

- Centrifugal Pumps Need Protection

When making use of centrifugal pumps in automatic recycling valve for liquid-boiler feeds and process fluids, an investment must be made specifically in the pump. Minimum flow protection is important in operation. Lack of reliable protection may lead to unfavorable impacts that can interfere with the pump’s operation.

- Disintegrating The Process Flow

The process flow removes the heat generated from the pump. As such, the temperature rises. The current via the pump is gradually reduced. A rise in temperature leads to the formation of vapor, which will then lead to reduced production of fluid.

- How The Continuous Circulating System Works

The average requirement of continuous circulation system pump is unrelated to the contents of the flow system. After setting a minimum flow by using the plate, the constant circulation protects the pump. This will provide greater power output, which will ensure that the system process flows.

- Disintegrating The Operation Of The Control Circulation System

The control circulatory system of the ARC pump valve is assembled by the check valve and flow gauge. The control circulation system will provide maximum flow if properly set up. The system is, however, complex. Maintenance is also higher.

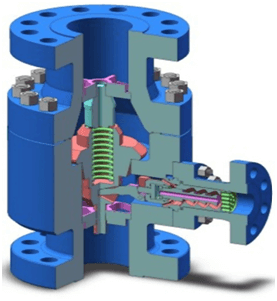

- Main Characteristics Of Automatic Recycling Valve

The ARC valve has several characteristics. It has a simple structure. This makes it easy to operate. It also has a few moving parts. Other than that, the device is easy to install. On a pump, it may be mounted vertically or horizontally. The bypass is relatively large with a maximum flow of 60%.

- A Look At The Valve Layout

An automatic recycle valve is best installed into the compatible outlet of the pump. The layout of the valve is based on its curve. It’s vital to ensure that these valves are mounted on the right pumps. Therefore, the direction of flow is written on the template to help in installation. On the same template, you’ll find the commissioning fabrication number of the ARC valve.

- The Working Principle

The difference in main flow allows the valve disc to move to a particular position. The valve disc drives past the bypass, thereby controlling the movement of the main disc into the bypass using a control bypass valve. The primary valve disc is pushed back into the valve seat. Prior to handling any maintenance on the pipes, the equipment should be stopped. This helps to relieve pressure. The valve is then closed.

Conclusion

When handling an ARC valve, you should evade resonance with the operating system. It’s also vital to note that when used with a damper, the pulsation needs to be mounted between the valve of the pump and the backpressure. During outdoor use, an individual should use a protective shed. Because this is a technical device, users must learn how to operate it.