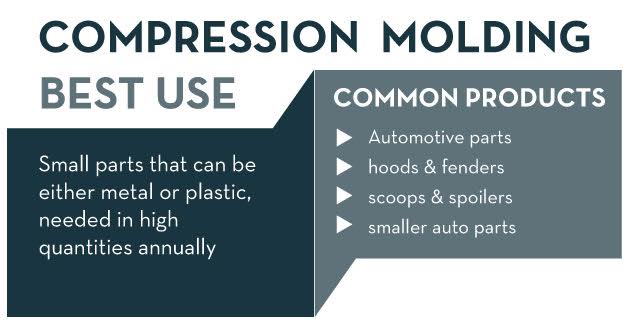

Compression molding process seems alien but is overly used. Though our paths cross you may not have related to this simple concept. Compression molding unlike other forms of molding places the preheated molding material into an open heated molded cavity. The preheated molding material is normally a polymer.

History of Compression Molding

When it was first created, the strategic objective of compression molding was to fabricate composite metal parts for substitution during applications. It has since been used in the manufacture of hoods, fenders, spoilers and scoops. Much smaller parts have been manufactured through this process though their intricacy still remains too oblivious for us to notice.

Compression Molding Process

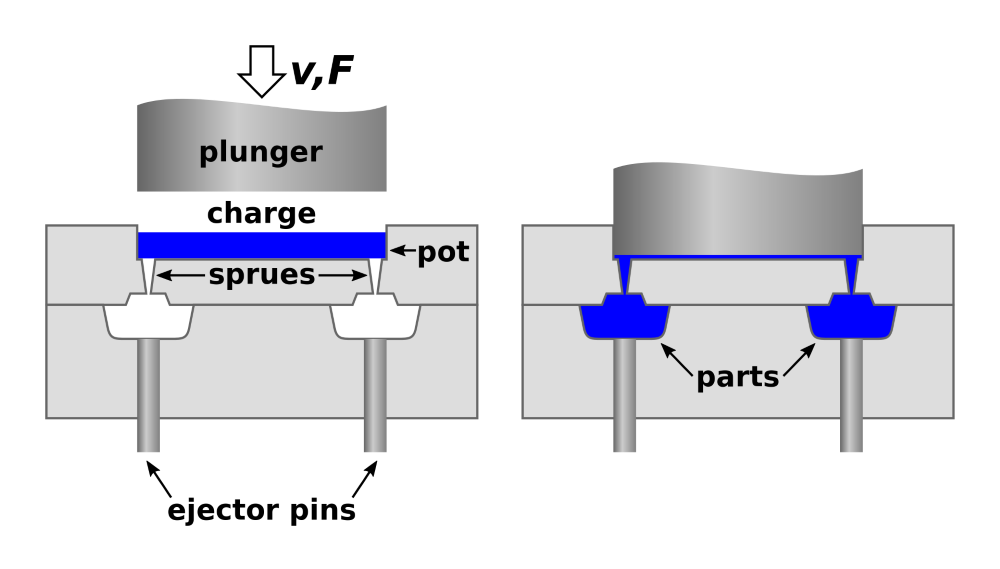

Close up the open molded cavity with a top plug for it to allow for compression and increase the surface area of contact for all areas of the mold. Like metal injection molding, this process is counters traditional manufacturing process by reducing operational costs in producing parts.

Once you shut the mold a best power or fitting part, you have to connect weight to drive the material into contact with all shape regions. Amidst this, heat and weight are to be kept up until the point when the material has cured.

The best thing about compression molding is its capacity to shape substantial, genuinely complex parts that would be generated by other molding forms but at a cost. It is also one of the most reduced cost shaping techniques contrasted and different strategies such as infusion forming and transfer molding.

Compression Molding Material and its Four Main Steps

Compression molding uses thermoset composites as its main raw material. During compression molding process, the thermoset composite implores the following four major steps:

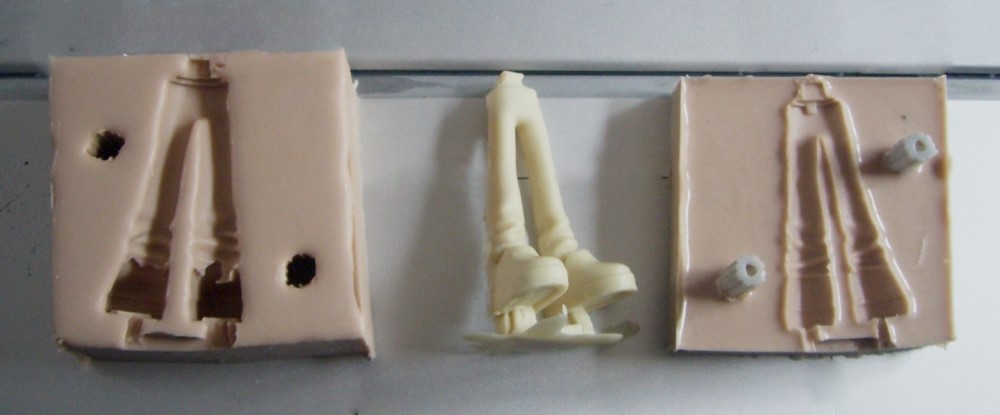

- Creation and installation of a two-part metallic tool. A high quality, two section metallic device is created and it should precisely coordinate with the measurements required to deliver the desired part. Once complete, place the instrument in a press and heat it.

- Pre-forms. The desired composite needs to be pre-framed into the shape of the device. Pre-framing is a significant step because this advancement will enhance the performance of the tool once it is complete.

- You then insert the pre-formed part into a heated mold. Depending on thickness of the part or the material which you initially used, you can decide on what pressure to compact the pre-formed part; usually 800psi to 2000psi.

The pressure enacted should be contingent to your pre-formed part if you want it to turn out to a desired shape.

- Resin residue. There is still residue which can remain after pressure is released and the tool has been removed. You have to remove any residue from the around the edges of the compressed part.

Compression Molding By-products

Compression molding is additionally appropriate for ultra-expansive essential shape creation in sizes past the limit of expulsion methods. The materials you can ordinarily make through compression molding include:

- Polyester

- fiberglass resin frameworks (SMC/BMC)

- Torlon

- Vespel

- Poly(p-phenylene sulfide) (PPS)

- Grades of PEEK

Compression Molding Applications

Compression molding is used to make large parts as well as parts which are moderately curved. This makes compression molding gain prowess in many applications, dominating the automobile turf.

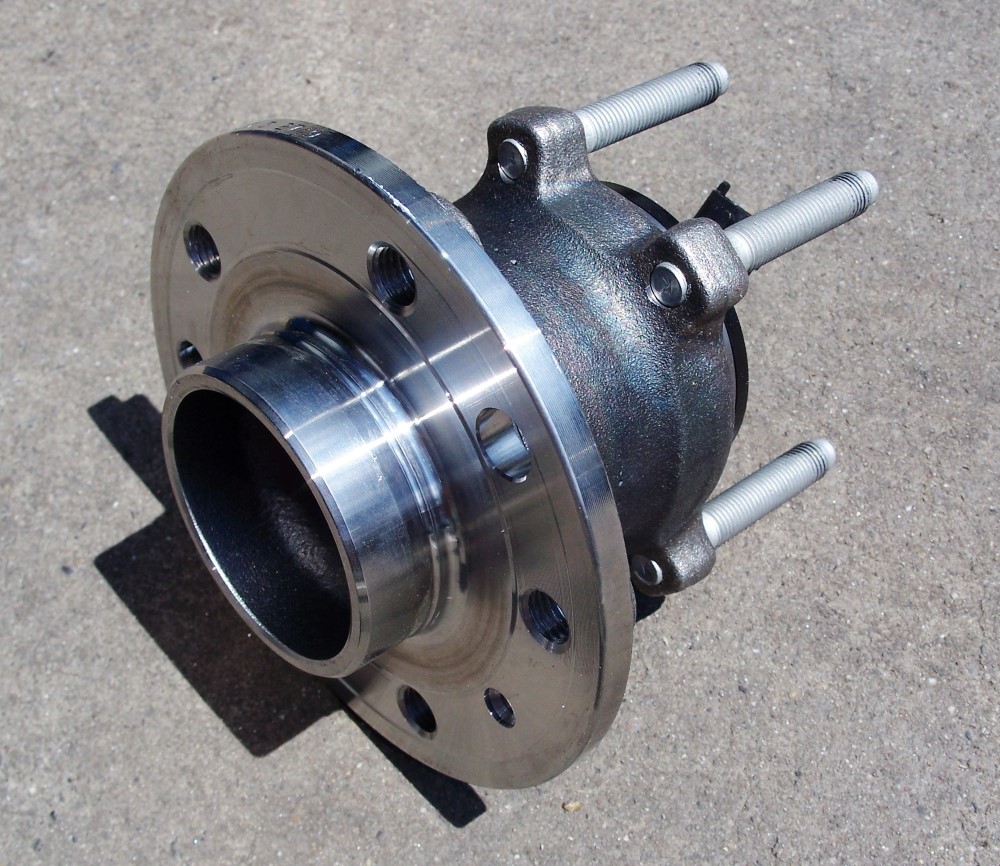

- Manufacturing automotive parts. This molding strategy is used to manufacture automotive parts. The hood, bumpers, scoops and spoilers and a smaller flare of intricate parts you will rarely notice.

Bulk Molding Compound and Sheet Molding Compound in Compression Molding

Bulk Molding Compound (BMC) and Sheet Molding Compound (SMC) find their way into compression molding. It all starts in the mold cavity with the mold material that is to be shaped and closed behind a hydraulic ram.

The mold material is fit in with the shape frame by the connected weight and warmed until the point that a curing response happens. SMC will help nourish the material while a huge chunk of it is sliced to adjust to the surface zone of the form. The shape is then cooled and the part removed.

Materials might be loaded into the shape as either pellets or sheet. Relatively it can be as a form to be stacked from a plasticating extruder. You need to heat material over their liquefying points after which they are framed and cooled. The all the more equally the material is dispersed over the form surface, the less stream introduction happens amid the compression stage.

Thermoplastic frameworks are ordinary in any large scale manufacturing businesses. One noteworthy case that you already know of is car applications. Here the main advancements are long fiber strengthened thermoplastics (LFT) and glass fiber tangle fortified thermoplastics (GMT).

Compression Molding Considerations

Compression Molding implores six essential considerations which as a specialist you ought to remember for the process to be flawless:

- Best measure. Deliberate the best possible measure/amount of material.

- Energy requirements. Decide on a base measure of energy to adequately heat the material.

- Time is an important component of pre-heating your material. You therefore need to decide on the base time required to heat the material.

- Heating technique. Now that we are past the threshold of time and energy, you need a standardized heating technique which you can tame for the whole process. You need a subtle heating method.

- Force analytics. Force is God in compression molding. Excess force gives material a disfigured shape. You have to foresee the expected power that guarantees that shot will help achieve the best possible shape.

- Mold design. The molded material is left to cool to give off heat. Mold design will either allow for rapid cooling or slow it down further.

Advantages of Compression Molding

- Use of advanced composites. In comparison with other metal parts, compression-molding materials are generally stronger, lighter, and stiffer and are more resistant to corrosion.

- Ability to create complex parts.

- The turnaround time and operation costs are the top priority of compression molding. This makes the process preferable to many manufacturers.

- It wastes little material which is advantageous when you’re working with expensive compounds.

Disadvantages of Compression Molding

- Poor item consistency.

- Inability to control glimmering/flashing.

Compression molding is the ‘average man’s resolve’. Looking at how much you can save when using expensive compound places compression molding at the apex of all molding. It even feats out injection molding as well as transfer molding.