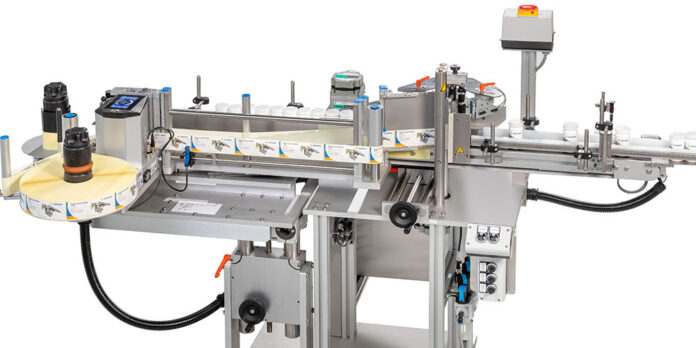

Shanghai Consung is a Chinese company that manufactures labeling and automated packaging equipment. The company makes a wide range of labeling and packaging machines used by the various establishment. Shanghai Consung boasts of working with thousands of companies in different countries like South Africa, Saudi Arabia, China, the UK, and the US. In this post, we discuss automatic labeling and the reasons why it has taken over the labeling industry.

Reasons why establishments are switching from manual to automatic labeling

Automatic labeling has taken over from manual labeling over the years. Here are some reasons why manual labelers are becoming obsolete;

1. Human error

One of the greatest challenges with manual labeling is the presence of human error. Humans are prone to making errors like placing the labels wrongly or damaging some of the labels because of mishandling. Most of these human errors are a result of fatigue. Manual labeling involves a long process that may take several hours.

This is especially the case if you have many products to label. In addition, the fatigue and injuries resulting from the lengthy process may result in the workers making mistakes. Traditionally, organizations would resolve the issue of human error by training their workers. However, even the best trained and disciplined workers are prone to having some lapses and slips.

2. Time-consuming

Another element about manual packaging that lets it become obsolete is that it is quite time-consuming. As mentioned earlier, labeling is a long process. From peeling to sticking the labels with the right precision by hand, this may take a very long time if you are dealing with several products. Therefore, manual labeling may take up to days, and the job may still not be complete.

3. Little to no adjustment

Additionally, manual labeling equipment offers little to zero adjustments. This element can result in inconsistencies in the labeling process. This is especially an issue with wrap labels. Manual labeling machines are prone to issues like twisting, bubbling, and flagging during the application process. This happens if the rollers are not correctly aligned with the container.

Also, if there is more than one label to add to a container, you will need to separate the equipment or do the process twice. For instance, if you want to add an expiration date or lot number to a container, you will need a separate machine. This is not an issue with automatic labelers because they can perform dual functions and offer adjustments.

Switching from manual to automatic labeling

Automatic labeling was introduced to solve the challenges above and the added benefits that they offer. Below are some of these benefits;

- Automatic labeling eliminates challenges like injuries caused by labeling by hand

- Automatic labeling is pretty fast as it can perform thousands of labeling tasks in a few hours

- Automatic labeling is affordable because it does not require human labor and does not take a lot of time

- Automatic labeling is largely independent of manual labor

Conclusion

The benefits listed above are some of the main reasons why automated labeling has wiped out the application of manual labeling equipment in various industries. The increased applications of automatic labeling have also led to a growth of the automatic labeling machine manufacturing industry.