Gravure printing is one of the leading methods of printing that the printing press industry has ever heard about. It has been around for several decades and will continue to be around because of its amazing benefits and ease of use. You can find more about gravure printing inks at https://www.laserengravingmanufacturers.com/gravure-printing-cylinder-engraving/

This article will talk about gravure printing ink. It will also talk about why you should and can only use this type of ink when you are using the gravure printing process. After that, this article will look into some of the amazing benefits of the gravure printing method and why you should get on the train if you haven’t.

If you’re ready, it’s time to begin!

What is gravure

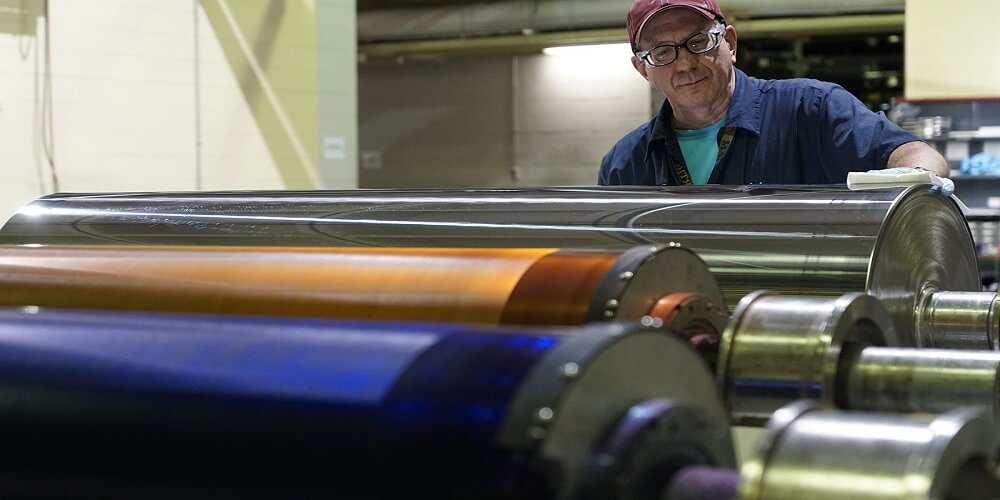

If you are a beginner in the printing press industry, you have to, first of all, know what gravure means so that you can understand why you can only use specific kinds of ink for the process. Gravure is a printing method that makes use of cylinders and cells for the purpose of printing.

The process involves the etching of a photo on several gravure cylinders. The photo will be given different dimensions and depths across all the cylinders. The cells in each cylinder would then be filled with the ink, which will be transferred to the substrate. The process is definitely easier than it appears on paper.

The ink used in gravure printing

The gravure printing process is one that is very versatile. However, one of its downsides is that it consumes a lot of ink. The gravure printing ink is of two types, namely, solvent-based and water-based. These two inks are sometimes used together or separately. What matters is the surface on which the printing job will be done.

1. The water-based ink

The water-based ink is most often used for packaging and requires really high temperature and a longer time in the drier. This process vaporizes the water content in it to make it available for use.

2. The solvent-based ink

The solvent-based ink uses the same process as the water-based one. The only notable difference is that it doesn’t require a lot of time in the drier. The solvent is absorbed by beds of activated carbon before it is stamped on the substrate.

Note that one common thing between these two is the removal of wetness from the inks. This is done to prevent smearing and smudging and to give you a neat job. From all this, you should already have seen some of the amazing benefits of gravure printing, and if you are new to the business, you should consider seeking professional help to guide you in the process while you master it.

Conclusion

The gravure printing ink automatically goes through the vaporization process. You don’t have to do anything about it. Also, note that flexo and gravure inks are the same, which means that you can run the printing process on gravure with flexo ink with ease, except that you will have to consume lots of it.